Hardware Assembiles

This post seeks to define the parts, materials and techniques for producing the following hardware assemblies for the collaborator gloves:

(1) Bend Sensor Assembly

(2) Ring Button Assembly

(3) LED Strip Assembly

(4) Motor Board Assemblies

(5) AA Battery Assembly

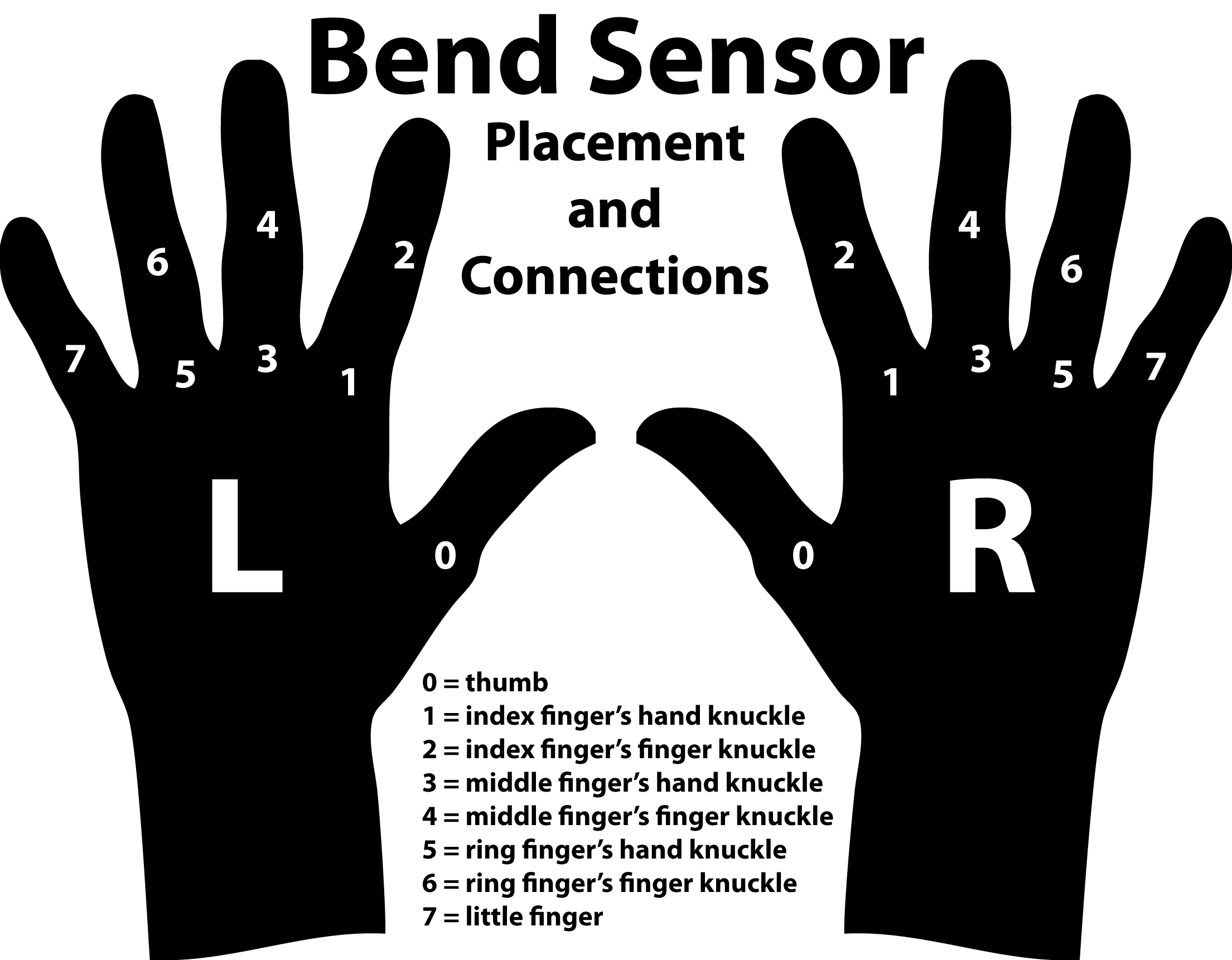

(1) Bend Sensor Assembly

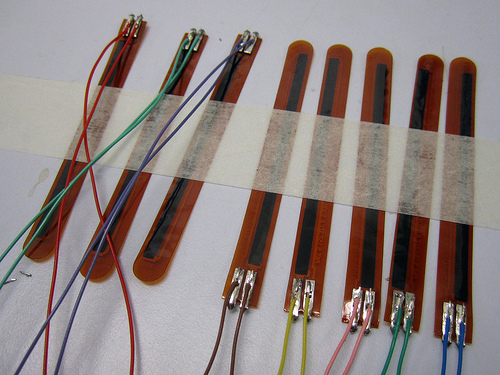

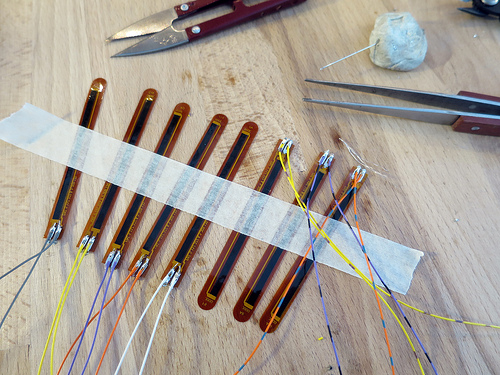

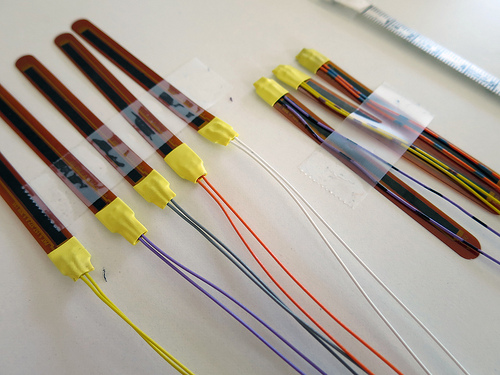

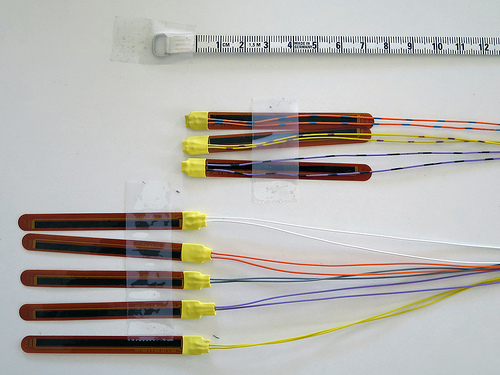

The bend sensor assembiles are made up of 8 bend sensors per assembly. Each sensor has two wires of identical length. The 5 hand knuckle sensors have 18cm long wires, the 3 finger knuckle sensors have 30cm long wires. One wire of each sensor is connected to an 8-pol mini JST connector row that goes to GND. The other wire of each sensor is connected to an 8-pol mini JST connector row that goes to the input pins of the x-OSC.

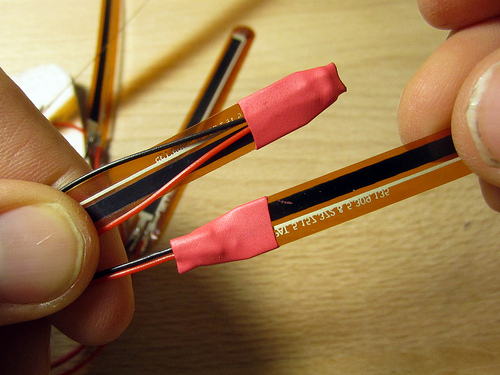

On the end of the bend sensor the wires are soldered to the bend sensor leads. Finger knuckle sensor leads are soldered to exit the sensor along the length of the sensor. Hand knuckle sensor leads are soldered to exit the sensor away from the sensor.

Parts:

- Flexpoint 3” polyimide laminate with NO blue connector attached!

- Shrink tube: SS 6,0/3:1 IK-1,2m — http://www.segor.de/shop?Q=$:25093

Part number: CMP250

>> http://www.eibmarkt.com/en/products/ABB-Stotz-S-J-T-B-Thin-walled-shrink-tubing-6-4-3-2mm-CMP250-9-A.html

>> http://en.elektrotools.de/Product/Heat-shrink-tubing-Thin-walled-2-1-6-4-mm-7TCA017300R0099

manufacturer >> http://www.tnb.com/pub/index.php

- Neoprene

>> http://sedochemicals.de/

- Cable loom

>> http://www.connect2t.co.uk/

Cable Loom:

These are the lengths i cut before stripping about 4mm off each end and soldering:

white (thumb): 18cm

yellow (index hk): 18cm

yellow stripe (index fk): 30cm

orange (middle hk): 18cm

orange stripe (middle fk): 30cm

purple (ring hk): 18cm

purple stripe (ring fk): 30cm

grey (little): 18cm

Shrink tube:

6mm diameter, cut to 11mm lengths

- hot melt glue on inside

- good shrink ratio

- minimal material thickness

Images:

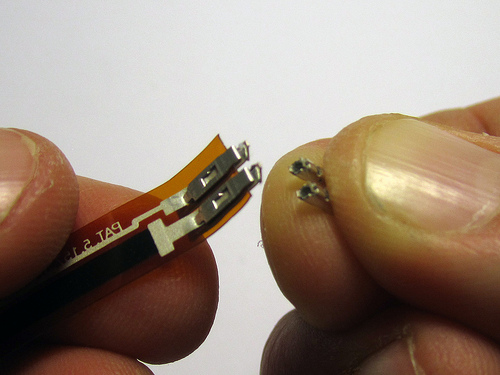

Before soldering remove extra metal from connector clipping off or bending back and forth until comes off.

Wires should be soldered to top side of sensors! (Top side = print side up!)

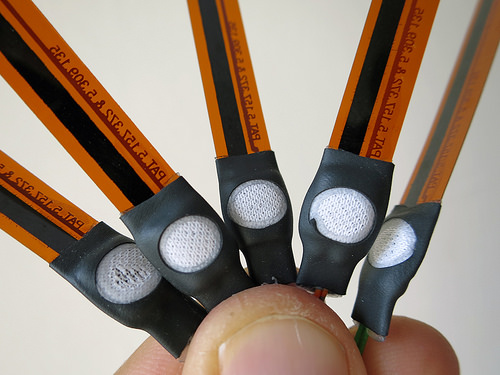

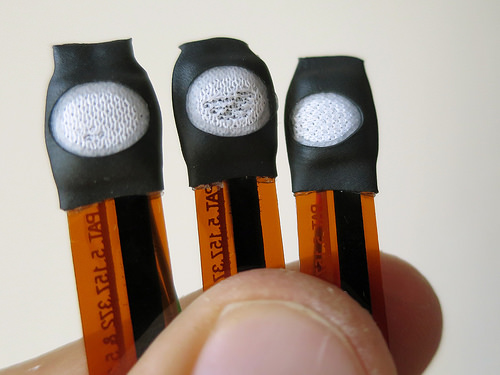

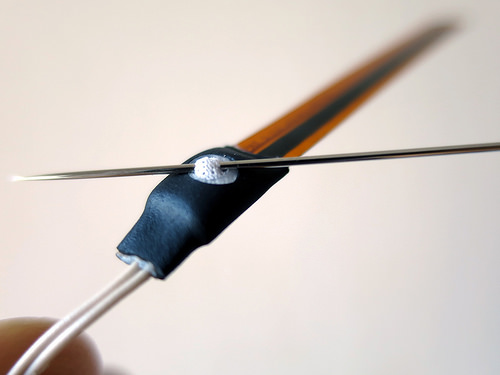

5 Hand knuckle sensor leads exit away from the sensor.

3 Finger knuckle sensor leads exit along the length of the sensor.

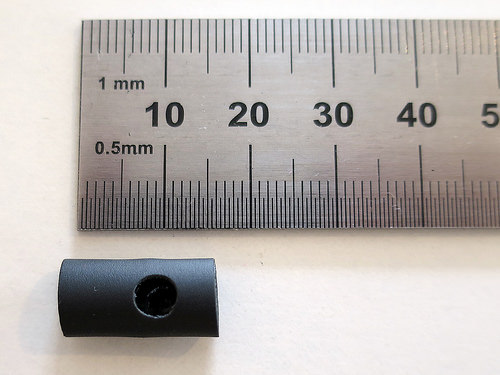

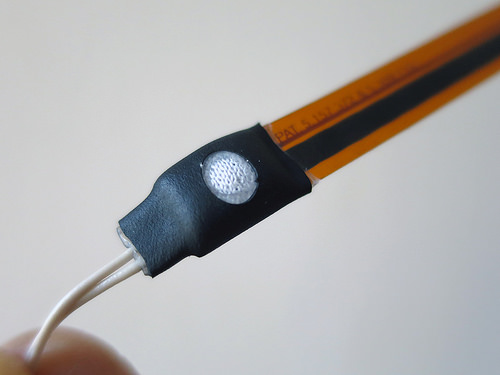

Roughly 15mm long piece of 6mm diameter shrink tube with hot-melt adhesive 3:1 shrink ratio. Hole is 4.5mm diameter (could maybe be 4mm or even 3mm). Distance from edge of shirnk tube to edge of hole on one side is 3.5mm, on other side 7mm. 9×9 mm square of 1mm thick neoprene with jersey fabric fused to either side. Square of neoprene is inserted under hole and then tube is shrunk. Because the fabric on neoprene is polyester jersey it melts if affected by hot air from shrinking tube. could be good to find fabric with less synthetic jersey.

Neoprene fabric should hold very well so that stitching to it does not cause it to come loose!

Images that show how wires are soldered to sensors:

Connections:

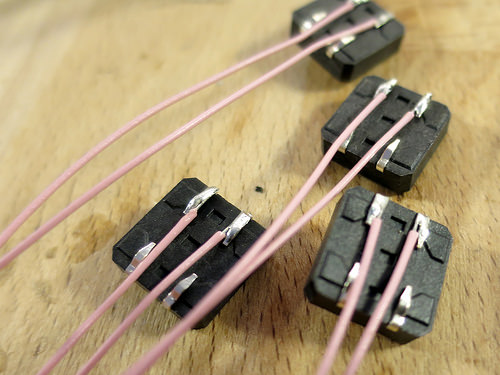

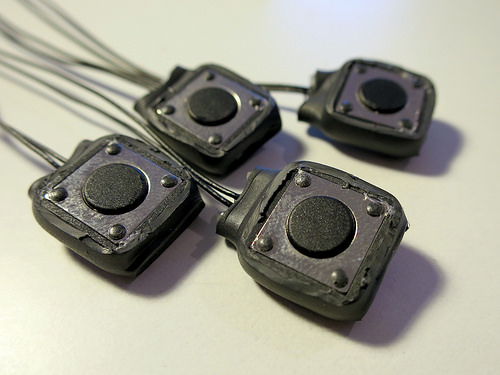

(2) Ring Button Assembly

Roughly 12 x 12 x 6mm button dimension with is good. Two 30cm long cables soldered to leads on back of button (see photos). Hole cut in shrink tube with hot-melt adhesive fused over button and then cut away to expose whole upper surface. Diameter and shrink-ratio of shrink tube to be finalized.

Parts:

- Black Button Tactile Switch, SPST 50 mA@ 24 V dc 0.5 mm >> http://uk.rs-online.com/web/p/tactile-switches/7182395/

- Shrink tube >> >> http://www.conrad.de/ce/de/product/604704

- Cable loom

Alternatives:

>> http://www.conrad.de/ce/de/product/700410

>> http://uk.farnell.com/schurter/1241-1601-11/switch-smd-push-ip40/dp/1217753

>> http://de.rs-online.com/web/p/tastschalter/7182395/

>> http://www.conrad.de/ce/de/product/700152/

Cables: two 30cm long wires that are flexible but strong to withstand minor pulls and tugs. colour marking?

Shrink Tube: need to find a way to strain-releve wires soldered to button contacts. Hole in shrink tube for access to button should be ?mm diameter.

Could also be something more like these earlier solutions:

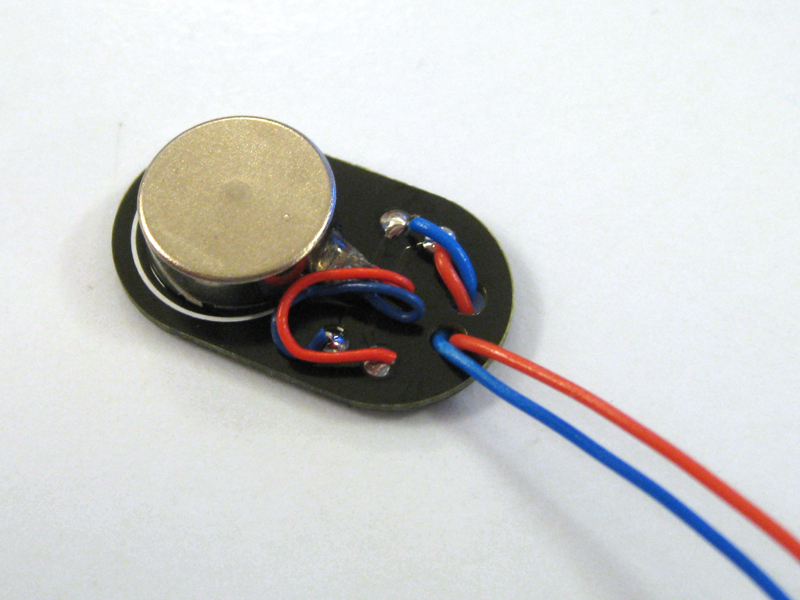

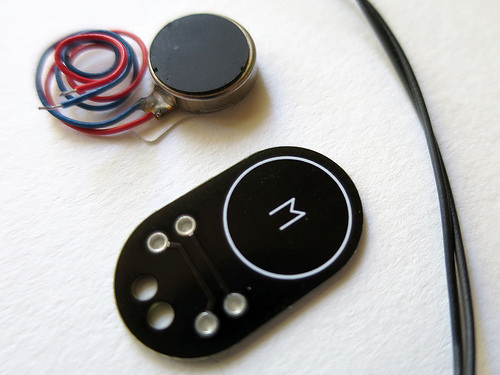

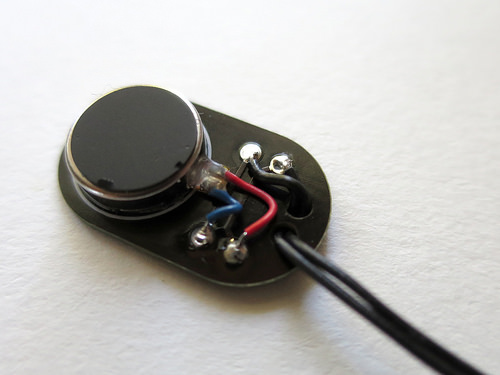

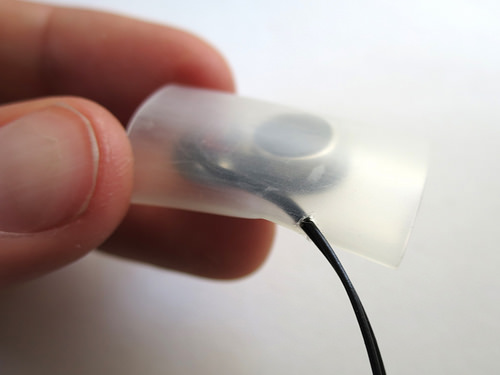

(3) Motor Board Assemblies

Parts:

- Motor board >> https://github.com/xioTechnologies/Gloves-PCB

- Motor >> https://www.sparkfun.com/products/8449

- Shrink tube >> >> http://www.conrad.de/ce/de/product/604704

- Cable loom

Cables

13cm

Shrink Tube

???

Images:

Front and back in shrink tube:

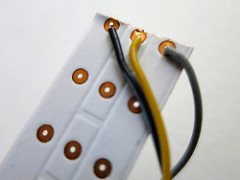

(4) LED Assembly

Three wires soldered to far end of NeoPixel LED strip. Schrink tube used in some way to cover and strain relieve wires that can run on back of LEd

Parts:

- Neopixels, 10cm strip of 13 LEDs >> https://www.coolcomponents.co.uk/digital-rgb-led-weatherproof-strip-144-led-1m-black.html#.

- Shrink tube >> >> http://www.conrad.de/ce/de/product/604704

- Cable loom

Cables

40cm

Images:

(5) AA Battery Assembly

Details >> http://theglovesproject.com/plotted-flex-aa-battery-holder/

Photos >> https://www.flickr.com/photos/plusea/sets/72157646646338654/

Parts:

See detail link above!

Cables:

Battery cables are 16cm long with JST on end.

MISC.

Segor

Wir koennen den von Ihnen gesuchten

Schrumpfschlauch ab Lager anbieten als Stueck zu 1,2m:

SS 6,0/3:1 IK-1,2m — http://www.segor.de/shop?Q=$:25093

oder als Boxen zu 5m;

SS 6,0/3:1 IK-Box 5m — http://www.segor.de/shop?Q=$:23244

Versandkonditionen und -spesen siehe http://www.segor.de/#/versand .

Nessel Shrink Tube

Shrink tube with glue

MIT KLEBER SR 6,4 K : 2,2 >> http://www.nessel-elektronik.de/PolyOlefine/polyolefine.html#MIT-KLEBER

Autec Shrink Tube

for bend sensor assembly:

DERAY®-IAKT 3:1 6mm -> 2mm schwarz

DERAY®-I3000 6,4mm -> 2mm schwarz

for ring button assembly:

DERAY®-IAKT 3:1 12mm -> 4mm schwarz

DERAY®-I3000 9,5mm -> 3mm schwarz

DERAY®-I3000 6 12,7mm -> 4mm schwarz

Conrad Shrink Tube

with glue for button ring >> http://www.conrad.de/ce/de/product/604704

no glue for bend sensors >> http://www.conrad.de/ce/de/product/530905

Fabric Cable Covers

Plus cable covers for ringbutton…

Geflechtschlauch Polyester:

501001 GS-3 Innendurchmesser 1,00mm

501002 GS-4 Innendurchmesser 2,00mm

501003 GS-5 Innendurchmesser 3,00mm

501004 GS-6 Innendurchmesser 4,00 mm

[…] >> http://theglovesproject.com/hardware-assembiles/ […]