Nadja Makes a Pair of Gloves

Nadja took part in The Gloves Workshop at CTM this January and decided to build herself a pair of the ArduIMU gloves. Following our online DIY instructions, she is giving us valuable feedback, pointing out gaps in our documentation and giving us a real impression of what is involved when somebody tries to recreate our design. Thank you Nadja!!!

Images of Nadja’s Building Process

Sewing at the Nähinstitut am Moritzplatz:

Ops! When the fingers get sewn in, seams need to come undone:

Trying on the first finished glove (inside-out first to check the seams are all good):

Tracing armband pattern to neoprene:

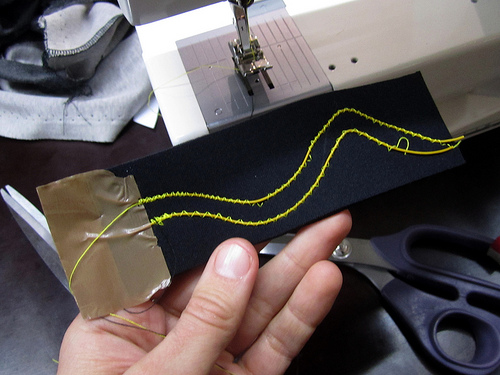

Practice sewing wire to neoprene:

Sewing at home with an Privileg Super Nutzstich Machine from ca. 1988

Problem: The machine can’t cope with the thick neoprene. Loosening the upper thread tension down to zero helped, but was not enough to ensure that the upper yarn was always connected tot he lower yarn. Moreover the machine pushes to one side. As a result one had to go several times over the wire and its still not clear wether this is sufficient.

Additional problem: the ironed fuse came partially off.

The marker is not visible on black. So marking was done with a tape.

This is how the left part looks now. I was first thinking that this forth-and-back sewing over the wire would look too ugly but now I find that the wild stitch has its special aesthetics and that I should eventually also do the right hand in this way, instead of going to Nähinstitut, where they have the good -but expensive- machines.

The wild stitching on the other side.

Despite the problems I used my Quelle-Privileg Machine with its stunning seventies/eighties Look

also for the Neopren of the right glove. For the seams of the battery pockets I had to rattle over

the seam four times though.

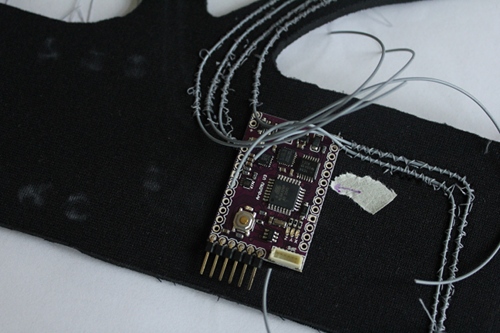

Soldering one board yet without the resistors and still with the need to check the connections.

The plastic of the wires was sometimes still too much visible so that wires of the cables were not really

forming a good nest around the cables. Hence the solderings got a bit messy and I am not sure wether the

connections are good.

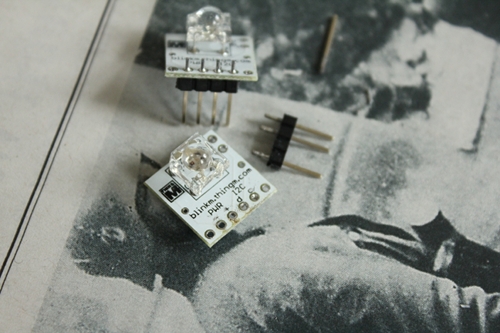

The LED modules come now automatically with a male header, which has to be unsoldered:

The bluetooth connection got a little better after reparing the batteries slack joint:

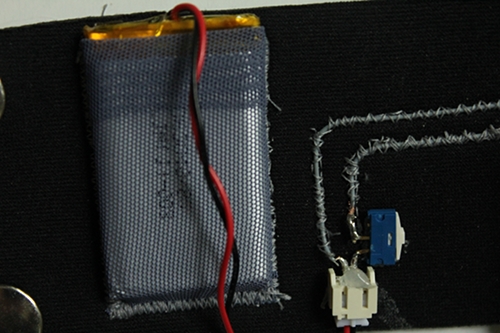

The JST battery socket turned out to have a slack joint that is the inside pins got loose and

where pushed out by the plug, so I fixed them with some hot glue (see image).

The Lipo battery chargers had by the way the same

problem, here the pins could be fixed again via soldering.

In addition getting the plug out of the socket was a very difficult and apart from broken finger nails

posed too much mechanical stress on the joints, so that I inserted a switch. (See blue-white part

from Segor electronics.)

After having done these fixes the bluetooth connection experiments got way better,

that is working with the bluetooth connection works now for a while,

but it still has to be seen wether the bluetooth connection is reliable enough like e.g. for performances.

Nadja’s gloves with bluetooth chip on them.

I wonder about the possibility using off-the-shelve gloves i.e. from diver-equipment? Wondering even more, I did not ask this earlier.

Greets to you guys, this project rocks!

[…] an ongoing project to make wearable non-standard musical controllers we found the vmeter which is a nicely sized touch […]

hey christoph. starting with an off-the-shelf gloves is possible. but then you have to sew the pockets for the bend sensors on by hand instead of being able to use the sewing machine. are you making a pair of gloves?

I am considering it seriously, but first I wanna try to convince some of our students to join in the process… reduce shipping costs, be more efficient with batch-workflows and so on.

As kind of a regular tech-guy I do feel somewhat ambiguos about real life stuff like… well, sewing for example! Maybe one of our students will volunteer though…