Bend Sensors Longevity Tests

We seem to be experiencing a change in the bend sensor’s behavior over time - an increasing hysteresis in the sensors recovery from bend over time. Bending the sensor results in an immediate increase in resistance, but straightening the sensor out, it takes a moment for the resistance to decrease again.

We are setting up a test rig to monitor how they might be changing over time.

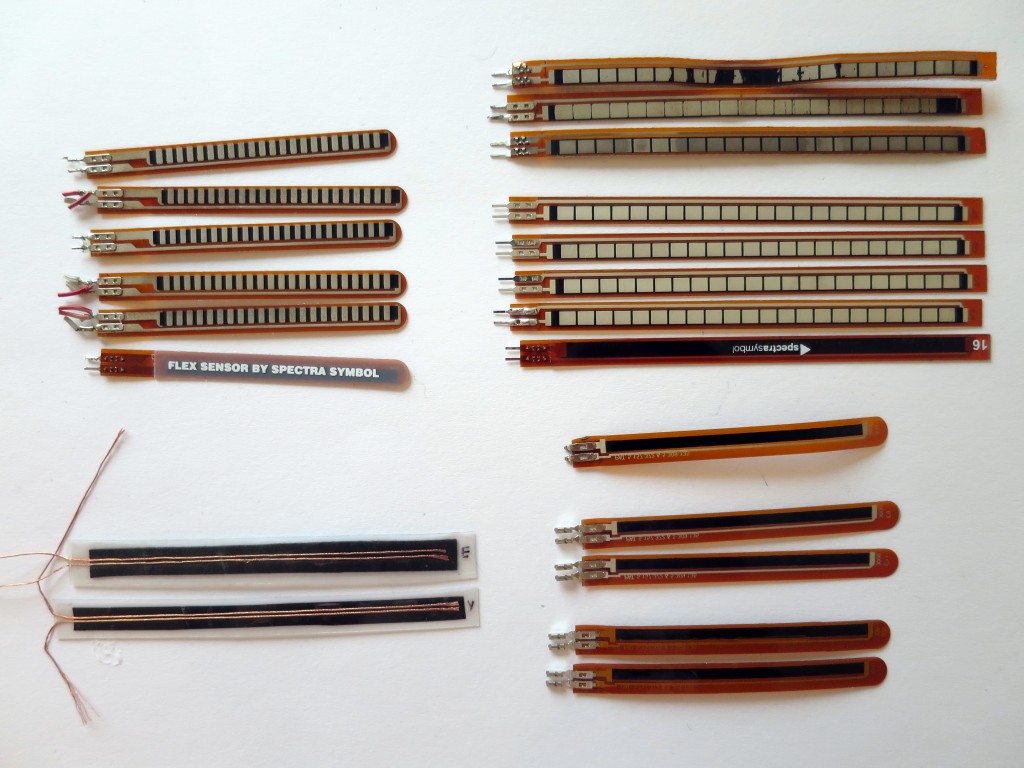

Bend sensors to test:

- Spectra symbol long and short

- Flexpoint 3” (no overlaminate, polyester overlaminate, polyiamide overlaminate)

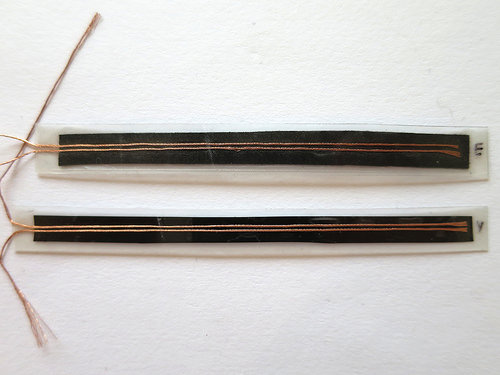

- Handmade bend sensors with conductive thread and Velostat/Eeonyx non-woven

Spectra symbol long and short

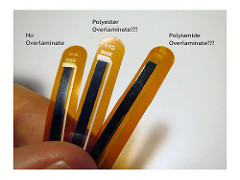

Flexpoint 3” (no overlaminate, polyester overlaminate, polyiamide overlaminate)

Materials:

The Polyester Overlamimnate is a 3M product 1 mil thick.

The Polimide Overlaminate is a Sheldahl product 1 mil thick #T161211.

The material that we print on is called Kapton.

Performance:

The sensors with Polyimide Overlaminate performed up to 30 million cycles without fail.

The sensors with Polyester Overlaminate performed up to 5 million cycles without fail.

Handmade bend sensors with conductive thread and Velostat/Eeonyx non-woven

It could just be me, but I didn’t understand the verdict. Which bend sensors ended up performing best? How did the hand-made sensors perform?

the tests have not been completed yet. but will post data as soon as we do!