3D Printed AA and AAA Battery Case

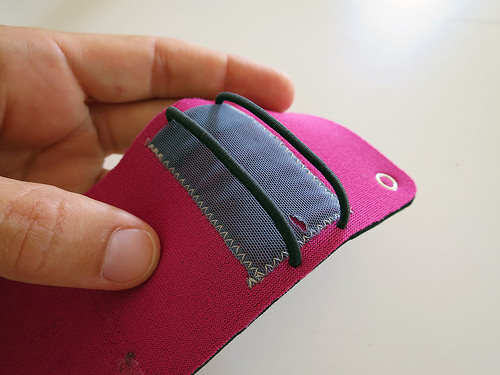

Instead of using the LiPo batteries to power the collaborator gloves, what about 3D printing custom cuff-mountable 3xAAA battery case? Alaina Appelbaum is working with us on a 3D printable 3 x AAA/AA battery case that mounts on the Mi.Mu glove cuff. This post documents the process of exploring this option.

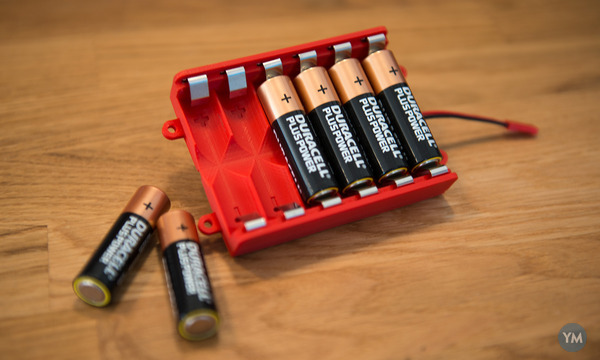

Battery Box by Flummer

Thanks Ingo for the link to this 3D model:

>> https://www.youmagine.com/designs/battery-box-for-aa-cells

Curvature Tests

Here is a first print of some curvature tests by Alaina to check how well the curve of the battery casing fits the curvature of a variety of wrists. Printed on an Ultimaker.

Download Illustrator, STL and OBJECT files >> rough model

Wall-Thickness Print Tests on Kelly’s Form1 Printer

Requirements/specs/relevant info:

- photos of current design >> https://www.flickr.com/photos/plusea/sets/72157644449012964/

- the cuff is currently made of 3mm thick neoprene with polyester-jersey fused to either side. snaps on either end of the cuff are how it is closed around the wrist.

- currently the lipo battery we are using sits in a netted fabric pouch on the bottom side of the wrist band. the battery leads come out from a corner of this pouch and curve around to the socket connector on the PCB mounted on the top of the wrist. location of battery socket will not change on new design of PCB.

- battery case should hold 3xAAA batteries in series. basically similar too this design >> http://www.weiku.com/products/10347460/3_AA_battery_holder_with_switch_cover_red_black_lead_wire.html

- for making electrical contact to the ends of the batteries use commercial contact elements (spring and cone-like disk). like these:

>> http://uk.farnell.com/okw-enclosures/a9176007/battery-clips-2xaa/dp/1236645

>> http://uk.farnell.com/keystone/5201/battery-holder-a-aa-1way/dp/1339845

- case design should curve with wrist to sit nicely on bottom side of cuff

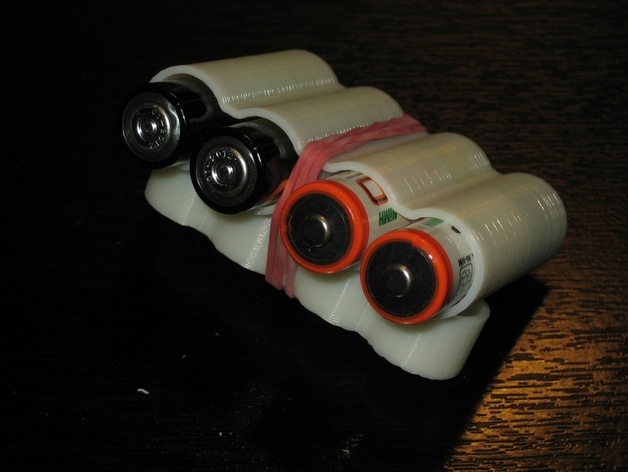

- case design should be able to mount on cuff. we are open to all kinds of ideas for how this could be done. as the cuff design will be finalized in september there is time to adjust it to work with the case design. one idea (see sketch) is to have the outer case design as 3 battery shaped pellets with groves between. elastic bands (purple) mounted on the cuff could be snapped over and into these groves to hold case in place.

- case should be really easy to open/close for replacing batteries when empty

- leads (positive and negative wires) should exit casing at same point, and at a position/angle that they nicely curve around to plug in to circuit board on top of wrist. length of wires has been 10-15 cm. possibly we would want to cover leads in fabric sleeve like these button cables >> https://www.flickr.com/photos/plusea/14419419689/in/set-72157645169552739

- the cost of each battery case should not exceed 7GBP, but you can forget about this requirement for now!

Not required for this iteration, but for future:

- on/off switch

- display of battery power status/battery meter

- cost of production (material, process…)

Quotes from Seb:

I am interested in the idea of using three AA cells to power the gloves. It seems that three Alkaline technology batteries in series would give us 4.5 V with a capacity of up to 2600 mAh; and Li-FeS would give us 3400 mAh. This would be 160% and 340% more capacity (i.e. battery life) than the 1000 mAh LiPo we have under the wrist right now. A battery life of 10 hours would not seem unfeasible!

The main draw back is that the ‘battery compartment’ needs to be designed and manufactured. We need to hold three cells in series in as robust way as possible. Furthermore, the batteries need to be quick and easy to insert/remove. My instinct is to get a competent industrial engineer to design this part; probably 3D printed.

Most devices for live performance use commonly available batteries (e.g. AA, AAA or CR3032) instead of rechargeable solutions. I interpret this to be a considered design decision.

The advantages of common batteries are:

- Commonly available in shops around the world

- Used by many other devices and so the user (or roadies) will likely already have stock / stock-management in place

- Designed to be inserted/removed frequently and easily (RE: JST)

- The above points are particularly significant for live performances where batteries must be guaranteed to be fully charged prior to a performance

- Does not require a charger which is additional hardware to loose or break (even if only USB cable)

- Shipping/transportation is far less hassle (RE: Lithium battery restrictions)

Seb’s models for wall-thickness tests

First Sketch and Prototype

Existing/Inspiration…

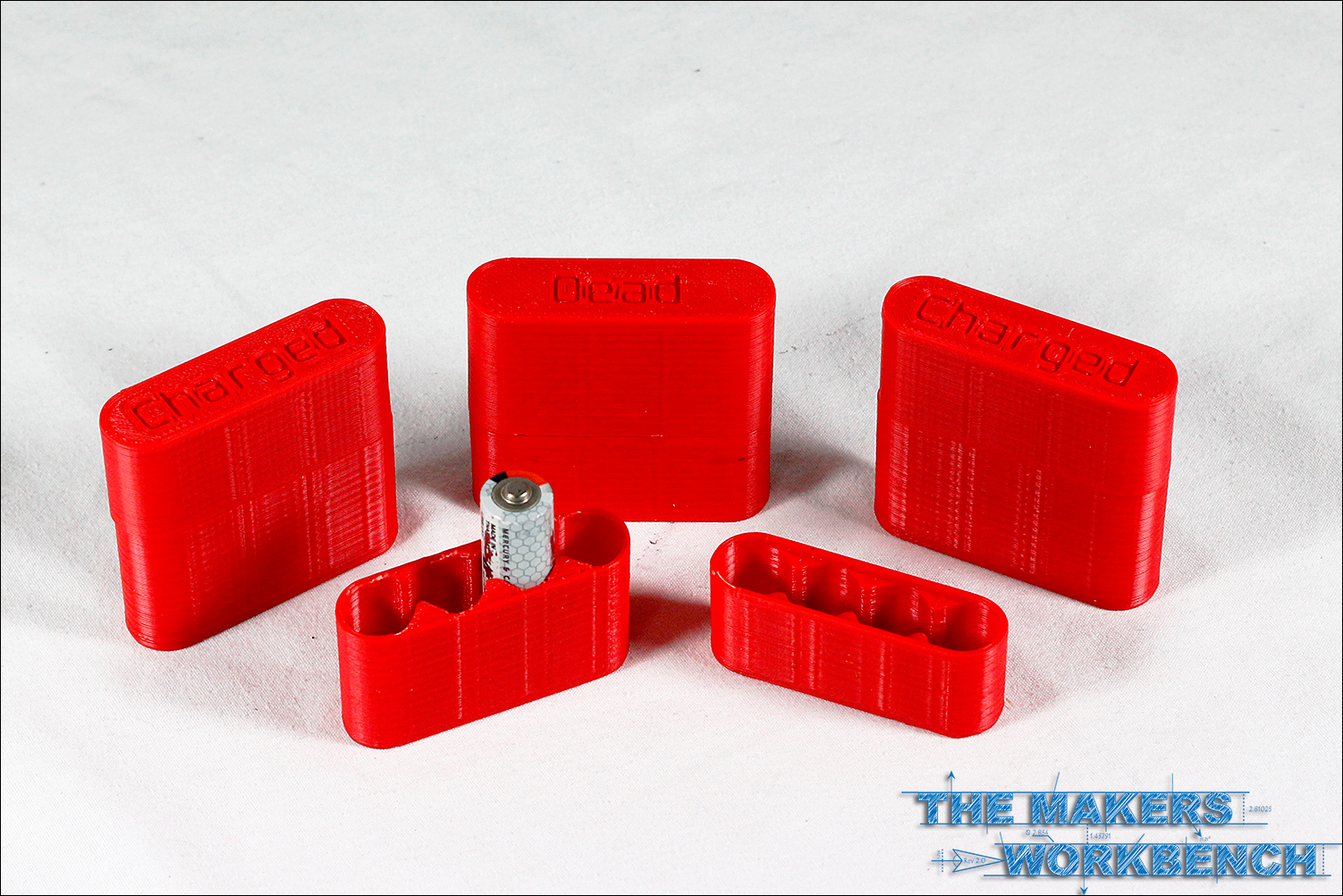

Customizable Battery Case (magnetic)

>> http://www.thingiverse.com/thing:51376

Battery box

>> http://www.thingiverse.com/thing:3602

4X AA Battery Case for Photographers

>> http://www.themakersworkbench.com/3D-printing/4x-aa-battery-case-photographers

3D Printed Battery Holders

How NASA Is Launching 3D Printing Into Space

>> http://www.space.com/24599-nasa-launches-3d-printing-in-space.html

Leave a Reply